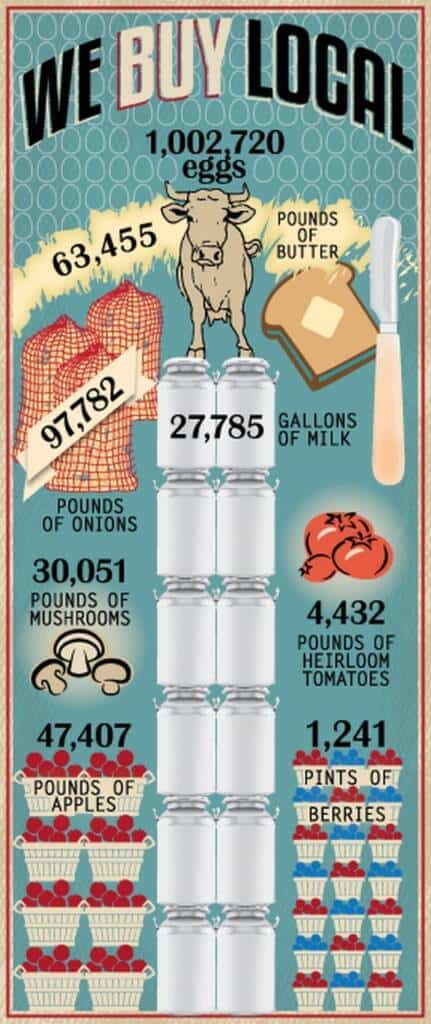

Though it may seem like we’re exaggerating when you consider the stats, be assured we are not.

We really do use that much dairy, we really do support that many farmers, and we really are moving toward a local and sustainable model at a pretty fast clip. On the Hyde Park, NY campus alone, we are cooking in 41 kitchens, four restaurants, and one alternative campus dining facility for students, faculty, and staff every day. With that in mind, think about the amount of foodstuffs we have to purchase. Then imagine our goal of being as sustainable an institution as we can be, and the challenges are many.

The team, under the leadership of Director of Purchasing and Storeroom Operations Brad Matthews ’74 in conjunction with Assistant Professor of Culinary Arts Darryl Mosher, strives to adhere to a sustainable food-purchasing plan of local, organic, and seasonal food. In Hyde Park, local means within a 250-mile radius of the Hudson Valley, “organic” means less toxicity though not necessarily a smaller carbon footprint, and “seasonal” means buying at peak season so fewer chemicals and energy are used to promote growth. Seasonal produce is of the highest quality and lowest cost due to the abundant supply available. Let’s take a look at what CIA in Hyde Park, NY is doing to meet its own expectations:

Fish

Just a few years ago, we were purchasing only 40% sustainable seafood as defined by Blue Ocean and the Monterey Bay Aquarium Seafood Watch. Today, we are at 80% and climbing. Brad and his team give chef-instructors color-coded lists of available fish, and Manager of Food Purchasing Anthony di Benedetto 98 works closely with them to offer alternatives that work within the curriculum.

Meat

We admit we have a distance to go until we are sustainable in this area. Most of our meat comes from New York City’s meat packing district. There are requirements for the humane treatment of animals, but we believe we can source alternatives in the future. We are, however, currently utilizing whole carcasses and other small quantities of local cuts for restaurant production and for teaching in our meat fabrication classes.

Eggs and Dairy

We are happy to report that we are 100% sustainable and almost completely local when it comes to egg and dairy purchasing. We buy all our eggs from local farmers, source half of our butter locally and the other half from Cabot Creamery in Vermont, and get cream and milk from Ronnybrook Dairy Farm up the road. No single cheese producer can make enough cheese to satisfy the needs of CIA, so we do business with eight to 10 local cheese producers in the Valley, to the tune of about $10,000–$15,000 a year each! Those farmers can count on our support for business.

Produce

Buying local produce whenever possible makes a huge difference in the flavor profile of the food our students are learning to cook. Local purveyors choose their varietals based on flavor and visual appeal. Large companies choose varietals based on how well they ship and length of shelf life. And while it’s high acidity that gives produce a better shelf life, it’s that same acidity that makes it harder to taste the items natural flavor. We meet with local growers often to let them know what types of produce we are looking for, based on curricular and restaurant needs. For example, our friends at Bulich Mushroom Farm send us 800 pounds of crimini, portobello, white, and oyster mushrooms every week, providing us with consistently high-quality products.

Fair and Domestic

The introduction of fair trade coffee at CIA came about as a result of collaboration between student clubs, Green Campus subcommittee members, the storeroom, dining services, and restaurant operations staff. We now also have fair trade chocolates, and have begun purchasing domestic rice and sugar rather than importing them. That means a smaller carbon footprint to get sugar into our coffee. As you can see, our team is continuing to push the boundaries of local, sustainable, and organic purchasing for the college. And the trajectory we are on is entirely positive. Stay tuned.

This article originally appeared in the Culinary Institute of America’s alumni magazine, mise en place.